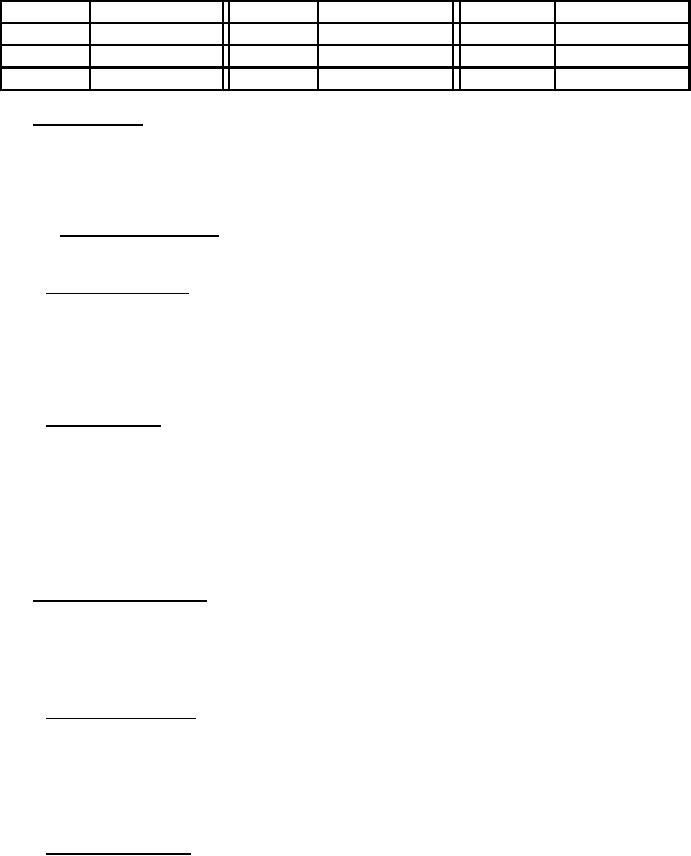

MIL-DTL-9479E (USAF)

3.2.13.1

4.5.1, 4.5.8

3.4.5.2

4.5.1, 4.5.10

3.2.13.2

4.5.1

3.4.5.3

4.5.4

3.2.13.3

4.5.1

3.4.5.4

4.5.4

3.2.13.4

4.5.1

3.4.5.5

4.5.6

4.2 Test conditions. Unless otherwise specified, all tests required by this specification shall be

made at an ambient pressure of 28 to 32 inches of mercury, a temperature of 75° ± 20°F, and a

relative humidity of 80 percent or less. When tests are made with atmospheric pressure,

temperature, or humidity substantially different from the above values, proper allowances shall be

made for the change in instrument readings.

4.3 First article inspection. First article inspection shall consist of all examinations and tests

described (see 4.5).

4.3.1 First article samples. The first article samples shall consist of:

a. One complete ejection seat system unless otherwise indicated in the approved

preproduction test plan.

b. Material samples as required to conduct the material tests specified herein.

4.3.2 Order of testing. Unless otherwise specified, tests shall be conducted in the following

order:

a. Any required component tests.

b. Structural and environmental tests.

c. Ground, track, and flight escape tests.

4.4 Conformance inspection. Conformance inspection shall consist of:

a. Individual inspection (see 4.4.1).

b. Sampling inspection (see 4.4.2).

4.4.1 Individual inspection. Each seat system shall be subjected to the following as described

(see 4.5):

a. Examination of product (see 4.5.2).

b. Ballistic gas transmission (4.5.3).

4.4.2 Sampling inspection. The sampling inspection shall consist of the following as described

(see 4.5):

a. Examination of preparation for delivery.

b. Structural strength.

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business